Wednesday, 26 December 2018

Monday, 3 December 2018

Hydraulic motor

From Antony Esposta

Hydraulic motors are actuators that can rotate continuously and as such have the same basic configuration as pumps. However, instead of pushing on the fluid as pumps do, motors are pushed upon by the fluid. In this way, hydraulic motors develop torque and produce continuous rotary motion. Since the casing of a hydraulic motor is pressurized from an outside source, most hydraulic motors have casing drains to protect shaft seals. There are three basic types of hydraulic motors: gear, vane, and piston. Let's first examine the operation and configuration of the gear motor.

A gear motor develops torque due to hydraulic pressure acting on the surfaces of the gear teeth, as illustrated in Fig. 7-22. The direction of rotation of the motor can be reversed by reversing the direction of flow. As is the case for gear pumps, the volumetric displacement of a gear motor is fixed. The gear motor shown in Fig. 7-22 is not balanced with respect to pressure loads. The high pressure at the inlet, coupled with the low pressure at the outlet, produces a large side load on the shaft and bearings. Gear motors are normally limited to 2000-psi operating pressures and 2400-rpm operating speeds. They are available with a maximum flow capacity of 150 gpm.

The main advantages of a gear motor are its simple design and subsequent low cost. Figure 7-23 shows a cutaway view of an actual gear motor. Also shown is the hydraulic symbol used in hydraulic circuits for representing fixed displacement motors.

Hydraulic motors can also be of the internal gear design. This type can operate at higher pressures and speeds and also has greater displacements than the external gear motor.

As in the case of pumps, screw-type hydraulic motors exist using three meshing screws (a power rotor and two idler rotors). Such a motor is illustrated in

Fig. 7-24. The rolling screw set results in extremely quiet operation. Torque is developed by differential pressure acting on the thread area of the screw set. Motor torque is proportional to differential pressure across the screw set. This particular motor can operate at pressures up to 3000 psi and can possess volumetric displacements up to 13.9 in..

Hydraulic motors are actuators that can rotate continuously and as such have the same basic configuration as pumps. However, instead of pushing on the fluid as pumps do, motors are pushed upon by the fluid. In this way, hydraulic motors develop torque and produce continuous rotary motion. Since the casing of a hydraulic motor is pressurized from an outside source, most hydraulic motors have casing drains to protect shaft seals. There are three basic types of hydraulic motors: gear, vane, and piston. Let's first examine the operation and configuration of the gear motor.

A gear motor develops torque due to hydraulic pressure acting on the surfaces of the gear teeth, as illustrated in Fig. 7-22. The direction of rotation of the motor can be reversed by reversing the direction of flow. As is the case for gear pumps, the volumetric displacement of a gear motor is fixed. The gear motor shown in Fig. 7-22 is not balanced with respect to pressure loads. The high pressure at the inlet, coupled with the low pressure at the outlet, produces a large side load on the shaft and bearings. Gear motors are normally limited to 2000-psi operating pressures and 2400-rpm operating speeds. They are available with a maximum flow capacity of 150 gpm.

The main advantages of a gear motor are its simple design and subsequent low cost. Figure 7-23 shows a cutaway view of an actual gear motor. Also shown is the hydraulic symbol used in hydraulic circuits for representing fixed displacement motors.

Hydraulic motors can also be of the internal gear design. This type can operate at higher pressures and speeds and also has greater displacements than the external gear motor.

As in the case of pumps, screw-type hydraulic motors exist using three meshing screws (a power rotor and two idler rotors). Such a motor is illustrated in

Fig. 7-24. The rolling screw set results in extremely quiet operation. Torque is developed by differential pressure acting on the thread area of the screw set. Motor torque is proportional to differential pressure across the screw set. This particular motor can operate at pressures up to 3000 psi and can possess volumetric displacements up to 13.9 in..

Wednesday, 17 October 2018

Working principle of Vernier Bevel Protractor

https://extrudesign.com/vernier-bevel-protractor/

Working

principle of Vernier Bevel Protractor

In Metrology, The

angular measurements are frequently necessary for manufacturing

industries. Vernier Bevel protractor is one of the angular measuring instrument

used for close tolerances. We are going to discuss the construction and the

working principle of the Vernier Bevel protractor in this article.

Vernier

Bevel Protractor

Bevel Protractors are

the Angular measuring devices. Vernier Bevel protractor is the simplest angular

measuring device which is having a Vernier Scale(Similar principle as the Vernier Calliper) along with the acute angle

attachment.

(The meaning of bevel is

which is not 90°)

Construction

of Vernier Bevel Protractor

Vernier Bevel protractor

consist of the following components.

1.

Main body

2.

Base plate stock

3.

Adjustable blade

4.

Circular Plate with

graduated vernier scale divisions.

5.

Acute angle attachment

The following figure

shows the vernier bevel protractor

·

The base plate(Stock)

consisting of the Working edge will be mounted on the Main body.

·

And the Acute angle

attachment is also mounted on the main body.

·

This acute angle

attachment can be readily attachable/detachable with the Locking Nut.

·

A circular plate having

a vernier scale in it, also mounted on the Main body frame.

·

This circular plate is

carrying an adjustable blade which can travel along its length and locked

at any position with the help of the blade locking nut.

·

The adjustable Blade one

end is bevelled at angles 45° and the other end is bevelled at 60°.

·

This Main body

frame itself having a graduated scale called the main scale.

·

The circular plate can

rotate freely on the main body.

·

There is a slow-motion

device which helps to control the rotation of the circular plate on the main

body.

This is the construction

of the Vernier Bevel Protractor

Working Principle of Vernier Bevel Protractor

1. As the Base Plate (Stock) acts as one of the working edges, and the other working edge will be the blade which is held on the circular plate. as you can see the some of the sample positions of the Vernier bevel protractor in action.

2. This Adjustment Blade

can be rotated along with the circular plate on the main body.

3. Which means the

vernier scale on the circular plate will be rotated on the Main scale which is

graduated on the Main body as shown in below.

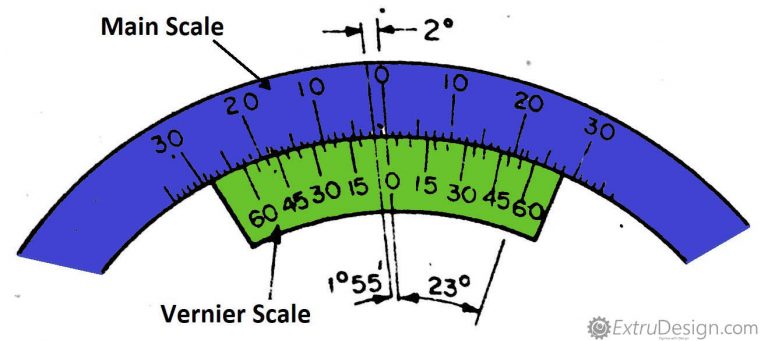

4. The Vernier scale has

12 divisions on each side of the centre zero. (It means there are 24 divisions

on the vernier scale)

5. The 12

divisions are denoted as 60 min on the vernier scale (Like this 15, 30,

45, 60). That means 12 division = 60 minutes

6. One devision= 60/12 =

5 minutes.

7. On the Main scale,

the same portion is represented as 23° (12 divisions on vernier scale = 23° on

the main scale )

8. One division on the

Vernier scale = 1.91666° = 1° 55′ (one degree 55 minutes).

9. As similar to the vernier calliper working principle as

Zero on the vernier scale moves on the main scale.

10. While taking a

measurement, The Zero line on the vernier scale shows the reading on the main

scale, called main scale reading.

11. At somewhere The

divisions on the vernier scale will coincide with the divisions on the Main

scale. this reading is noted as the Vernier scale reading.

12. With these values

along with the least count of the Vernier bevel protractor, we can calculate

the Reading.

See the following

example how to calculate the total reading

Measurements

with Vernier Bevel Protractor

Consider the Following

is a reading of an angular measurement.

The total

reading =the main scale reading + the number of the

division at which it exactly coincides with any division on the main

scale × least count of the vernier scale.

In the above case

The main scale reading =

10°

Vernier scale

reading (the number of the division at which it exactly coincides with any

division on the main scale) = 3rd division

Least count of the

vernier Bevel protractor = 5 Minutes

The total reading =

10°+15 minutes = 10 + (15/60) = 10.25°

Saturday, 15 September 2018

CIM April -2014 Question Paper

CIM April -2014 Question Paper

234

April -2014

Part A

1. List the benefits of CIM.

2. What is CAD?

3. What is graphics standard?

4. What is 3D rotation?

5. List the benefits of CAM.

6. What is GT?

7. What is Master production schedule?

8. What is sequential engineering?

9. Define DNC?

10. Mention the advantages of of CNC machines.

11. What is ATC?

12. What is an encoder?

13. What is conversational programming?

14. What is a datum point?

15. What is macro?

16. Mention the syntax for threading cycle.

17. What is FMS?

18. What is virtual machining?

19. Define robot.

20. What is AGV?

Part B

21. A. i. Explain the activities of CIM wheel. - 6

ii. Explain the guidelines of design for manufacture and assembly. - 6

Or

B. i. Explain the activities of CAD in Shigley's design process. - 6

ii. Explain the 3D rotation and 3D translation. - 6

22. A. i. Explain the generative type CAPP. - 6

ii. Explain the MRP - I. - 6

Or

B. i. Explain the code system. - 4

ii. What is RPT? Explain the stereo lithography method. - 8

23. A. i. Explain the working principle of CNC system. - 6

ii. Explain about the the design considerations of NC machine tools. - 6

Or

B. i.. Explain the working principle of EDM die sinking machine. - 6

ii. Explain about the ATC. - 6

24. A. i. Explain the NC dimensioning methods with example. - 6

ii. Write a part program for thread cutting operation in a CNC lathe. - 6

Or

B. i. Write a part program for pocketing in a CNC milling machine. - 6

ii. Explain about the tool offsets and tool compensation . - 6

25. A. i. Explain about the FMS components. - 6

ii. Explain the intelligent manufacturing system. - 6

Or

B. i. Explain the working principle of AGV. - 6

ii. Explain any two industrial applications of robot. - 6

Saturday, 1 September 2018

Wednesday, 15 August 2018

Wednesday, 8 August 2018

Sunday, 5 August 2018

Saturday, 5 May 2018

CNC PROGRAMS IN TURNING :: M SCHEME

EX. 1

BILLET : 32 mm dia. rod

O1101

G21 G98

G28 U0 W0

T0101

M03 S1200

G00 X32 Z2

G71 U0.5 R1

G71 P10 Q20 U0 W0 F20

N10 G01 X0

G01 Z0

G03 X16 Z-8 R8

G01 X16 Z-16

G02 X24 Z-20 R4

G01 X24 Z-35

G01 X30

G01 X30 Z-43

N20 G01 X34

G28 U0 W0

M05

M06 T02

M03 S500

G00 X28

;(assume a grooving tool of 2 mm width)

G00 Z-33

G75 R1

G75 X20 W-2 P500 Q250 F50

G28 U0 W0

M05

M30

*********************************************************************************

EX. 2

G21 G98

G28 U0 W0

T0101

M03 S1200

G00 X32 Z2

G71 U.5 R1

G71 P10 Q20 U0 W0 F20

N10 G01 X0

G01 Z0

G03 X16 Z-8 R8

G01 X16 Z-16

G02 X24 Z-20 R4

G01 X24 Z-30

G01 X30 Z-40

G01 Z-48

G01 X32 Z-48

N20 G01 X34 Z-48

G28 U0 W0M05

M30

*********************************************************************************

EX. 3

O1103

G21 G98

G28 U0 W0

T0101

M03 S1200

G00 X32 Z2

G71 U0.5 R1

G71 P10 Q20 U0 W0 F20

N10 G01 X10

G01 Z0

G01 X16 Z-3

G01 X16 Z-25

G01 X24 Z-25

G01 X24 Z-38

G01 X30 Z-38

G01 X30 Z-48

N20 G01 X34

G28 U0 W0

M05

M06 T02

M03 S250

G00 X28

G00 Z-22

G75 R1

G75 X10 W-3 P500 Q250 F50

G28 U0 W0

M05

M06 T03

M03 S150

G00 X16 Z5

G76 P041560 Q150 R0.1

G76 X13.546 Z-20 P1227 Q200 F2

G28 U0 W0

M05

M30

BILLET : 32 mm dia. rod

O1101

G21 G98

G28 U0 W0

T0101

M03 S1200

G00 X32 Z2

G71 U0.5 R1

G71 P10 Q20 U0 W0 F20

N10 G01 X0

G01 Z0

G03 X16 Z-8 R8

G01 X16 Z-16

G02 X24 Z-20 R4

G01 X24 Z-35

G01 X30

G01 X30 Z-43

N20 G01 X34

G28 U0 W0

M05

M06 T02

M03 S500

G00 X28

;(assume a grooving tool of 2 mm width)

G00 Z-33

G75 R1

G75 X20 W-2 P500 Q250 F50

G28 U0 W0

M05

M30

*********************************************************************************

EX. 2

G21 G98

G28 U0 W0

T0101

M03 S1200

G00 X32 Z2

G71 U.5 R1

G71 P10 Q20 U0 W0 F20

N10 G01 X0

G01 Z0

G03 X16 Z-8 R8

G01 X16 Z-16

G02 X24 Z-20 R4

G01 X24 Z-30

G01 X30 Z-40

G01 Z-48

G01 X32 Z-48

N20 G01 X34 Z-48

G28 U0 W0M05

M30

*********************************************************************************

EX. 3

O1103

G21 G98

G28 U0 W0

T0101

M03 S1200

G00 X32 Z2

G71 U0.5 R1

G71 P10 Q20 U0 W0 F20

N10 G01 X10

G01 Z0

G01 X16 Z-3

G01 X16 Z-25

G01 X24 Z-25

G01 X24 Z-38

G01 X30 Z-38

G01 X30 Z-48

N20 G01 X34

G28 U0 W0

M05

M06 T02

M03 S250

G00 X28

G00 Z-22

G75 R1

G75 X10 W-3 P500 Q250 F50

G28 U0 W0

M05

M06 T03

M03 S150

G00 X16 Z5

G76 P041560 Q150 R0.1

G76 X13.546 Z-20 P1227 Q200 F2

G28 U0 W0

M05

M30

Sunday, 15 April 2018

Saturday, 7 April 2018

FLUID MECHANICS AND FLUID POWER : Board Exam Questions for Diploma

321

October 2017

Time — Three hours

(Maximum Marks: 75)

(N.B: (1) Q.No. 8 in PART - A and Q.No. 16 in PART - B are compulsory. Answer any

FOUR questions from the remaining in each PART - A and PART - B.

(2) Answer division (a) or division (b) of each question in PART-C.

(3) Each question carries 2 marks in PART — A, 3 marks in Part — B and 10 marks in PART - C.)

PART-A

1. What is meant by pressure head? (October 2017)

2. Define compressibility. (October 2017)

3. What is turbulent flow? (October 2017)

4. Write down the formula to find the theoretical discharge of a double acting reciprocating pump. (October 2017)

5. What are the different types of impellers used in centrifugal pumps? (October 2017)

6. Draw the ISO symbol of FRL unit. (October 2017)

7. What is 3/2 DCV? (October 2017)

8. State any two demerits of hydraulic systems. (October 2017)

PART-B

9. Explain the method of measuring local atmospheric pressure. (October 2017)

10. What is continuity equation? Explain. (October 2017)

11. State Bernoulli’s theorem and write its few applications. (October 2017)

12. Write the expression for the work done by the jet on a series of moving plates on the circumference of a revolving wheel. (October 2017)

13. State the difference between Kaplan turbine and Francis turbine. (October 2017)

14. What is FRL unit? Explain briefly. (October 2017)

15. Explain the working of a pressure regulator. (October 2017)

16. List out the elements of hydraulic system with a line diagram. (October 2017)

PART-C

17. (a) (i) A gauge fitted to a compressor shows a reading of 3OkN/m2. Compare the corresponding absolute pressure in (a)kN/m2 and (b) “m” of water. (October 2017)

(ii) Explain the working of hydraulic jack with a neat sketch. (October 2017)

(Or)

(b) (I) What are the precautions to be followed in setting up and

operation of manometer? (October 2017)

(ii) Explain the working of Bourdon tube pressure gauge with a simple sketch. (October 2017)

18. (a) (i) What are the hydraulic co-efficients? Explain briefly. (October 2017)

(ii) Using Chezy’s formula, determine the head lost due to friction in a pipe of 80mm diameter and 35m length. The velocity of flow is 2 m/s and C=100. (October 2017)

(Or)

(b) (i) Compare Venturimeter and Orificemeter. (October 2017)

(ii) Two reservoirs are connected by a pipe line of length 500m. The difference in level between the reservoirs is l0 m. If the maximum discharge is 0.2m3/s, calculate the required size of the pipe. Assume f=0.005. (October 2017)

19. (a) A jet of water 80 mm diameter moves with a velocity of 15 m/s and strikes a series of vanes moving with a velocity of l0 m/s. Find (a) the force exerted by the jet, (b) work done by the jet per second and (c) efficiency of the jet. (October 2017)

(Or)

(b) Explain the governing of Pelton wheel with a neat sketch. (October 2017)

20. (a) (i) Explain the use of shuttle valve in pneumatic circuits. (October 2017)

(ii) List out the merits of pneumatic system. (October 2017)

(Or)

(b) (i) Explain the working of 5/2 DCV with a neat sketch. (October 2017)

(ii) Draw the circuit diagram for the direct control of single acting cylinder and explain. (October 2017)

21. (a) (i) Explain the spring loaded type accumulator. (October 2017)

(ii) Explain radial piston pump with sketch. (October 2017)

(Or)

(b) (i) Explain the various essential qualities of a good hydraulic fluid. (October 2017)

(ii) Explain the hydraulic circuit used for the table movement of a surface grinding machine. (October 2017)

***************************************************************************************

***************************************************************************************

April 2017

PART-A

1. Define viscosity of a fluid.

2. State Pascal’s law.

3. What is an orifice?

4. Define co-efficient of contraction.

5. What is a draft tube?

6. Draw the ISO symbol of 5/3 DCV.

7. What is the use of accumulator?

8. Define negative slip. In which type of pumps it will occur?

PART—B

9. Distinguish between cohesion and adhesion.

10. Define wetted perimeter and hydraulic radius.

11. Differentiate impulse and reaction turbines.

12. Describe about indicator diagram.

13. List out the elements of pneumatic system with a line diagram.

14. What is the purpose of quick exhaust valves used in pneumatics system?

15. State any three advantages of hydraulic system.

16. What are the objectives of adding additives to hydraulic oil?

PART-C

17. (a) (i) Explain the terms atmospheric pressure, gauge pressure and vacuum pressure.

(ii) Explain the working of hydraulic press with neat sketch.

(Or)

(b) (I) Explain the working of dead weight pressure gauge with a simple sketch.

(ii) An inverted U-tube differential manometer is connected to measure the difference of pressure between two points of horizontal pipe line carrying water. The gauging liquid is an oil of specific gravity 0.8. Find the difference of pressures, if the manometer reading is 0.4 m.

18. (a) (i) Derive Chezy’s formula for the loss of head due to friction in pipes.

(ii) Compare the velocities of flow of water in two pipes of diameter 160mm and 220mm respectively, when the loss of head due to friction, length of pipe and the value of ‘f’ are same for each pipe.

(Or)

(b) (i) State the laws of fluid friction in laminar flow.

(ii) State the advantages and Limitations of Bernoulli’s theorem.

19. (a) (i) Explain the working of impulse turbine with a neat sketch.

(ii) Compare piston and plunger pumps.

(Or)

(b) (I) Explain any one type of casing employed in centrifugal pumps.

(ii) State the advantages of air vessels used in reciprocating pumps.

20. (a) (i) Explain the working of a 5/2 DCV in pneumatics.

(ii) Draw the circuit diagram for the operation of a double acting cylinder with metering-in control.

(Or)

(b) Explain the automatic operation of double acting cylinder with a circuit.

21. (a) (i) Explain the working of internal gear pump with a simple sketch.

(ii) Explain the working of any one type of accumulator with sketch.

(Or)

(b) (i) Explain the table movement of milling machine with a hydraulic circuit.

(ii) Compare pneumatic and hydraulic systems.

******************************************************************

704

October 2016

Time — Three hours

(Maximum Marks: 75)

(N.B: (1) Answer any fifteen

questions in PART — A and division (A) or division (B) of each question in PART

- B.

(2) Each question carries 1

(one) mark in PART — A and 12 (twelve) marks in PART - B.)

PART-A

1. Define absolute pressure.

2. Define Pascal’s law.

3. What is pressure head?

4. What is the use of micro

manometer?

5. What is laminar flow?

6. State any two assumptions are

considered in deriving Bernoulli’s theorem.

7. What is wetted perimeter?

8. What are the types of venturimeter?

9. Differentiate Francis and

Kaplan turbines.

10. What is the purpose of draft

tube?

11. Why do you need to priming?

12. Define slip.

13. Draw the ISO symbol for FRL

unit.

14. What is the use of quick

exhaust valve?

15. What is meant by 5/3 DCV?

16. Write any two demerits of

pneumatic system.

17. What is Lubricity of fluid?

18. What is pressure

intensifier?

19. Draw the ISO symbol of 4/2

DCV.

20. Mention any two service

properties of hydraulic fluid.

PART-B

21. (A) (I) Explain about diaphragm pressure gauge. (ii) Explain about hydraulic press with neat sketch.

(Or)

(B) (i) Explain about gauge

pressure, vacuum pressure, atmosphere pressure and absolute pressure.

(ii) A pipe contains an oil of

specific gravity 0.8. A differential manometer connected at the two points A

and B of the pipe shows a difference in

mercury level as 20 cm. Find the difference of pressure at the two points.

22. (A) Derive an expression for

the discharge through venturimeter.

(Or)

(B) (I) Using Chezy’s formula,

find the loss of head due to friction in a circular pipe 40m long and 100mm

diameter when the velocity of flow is 2.4 m/sec. Take C=100.

(ii) Explain any four minor

losses occurred in flow through pipes.

23. (A) (i) A jet of water 65mm

diameter moves with a velocity of 12m/s and strikes a series of vanes moving

with a velocity of 9m/s. Find (a)co-efficient of jet (b)force exerted by the

jet (c)work done by the jet.

(ii) Explain the working of

submersible pump with neat sketch.

(Or)

(B) (I) Explain the working

principle of reciprocating pump with neat sketch.

(ii) A double acting

reciprocating pump having a piston area 0.2 m2 has a stroke of 0.4 m.

The pump is discharging 50 lps water at 50 rpm through a total height of l0 m. Find (i)the slip of the piston (ii)power

required to drive the pump.

24. (A) (i) Explain about the

uses of quick exhaust valves in pneumatic systems with neat sketches.

(ii) Explain about FRL unit with

neat sketch.

(Or)

(B) (i) Explain the operation of

double acting cylinder with metering in control with neat sketch.

(ii) List out the applications

of pneumatic system.

25. (A) (i) Explain about gas filled

accumulator with neat sketches.

(ii) Explain about radial piston

pump with neat sketch.

(Or)

(B) (i) Explain about hydraulic

circuit for table movement in surface grinding machine.

ii Draw a spring loaded type

accumulator and mark the parts

*******************************************************

628

April 2016

Time - Three hours

(Maximum Marks: 75)

(N.B: (1) Answer any fifteen questions in

PART — A and division (A) or division (B) of each question in PART - B.

(2) Each question carries 1 (one) mark in

PART - A and 12 (twelve) marks in PART - B.I

PART—A

1. Define ideal fLuid.

2. What is pressure head of a fluid?

3. Define Pascal’s law.

4. What is the use of dead weight pressure

gouge?

5. What is turbulent flow?

6. Mention any two energy losses not

considered in Bernoulli’s theorem.

7. Define Bernoulli’s theorem.

8. What is wetted perimeter?

9. Differentiate impulse and reaction

turbines.

10. What is the function of surge tank?

11. What is cavitation?

12. What is negative slip?

13. What is FRL unit?

14. What is the function of a relief valve?

15. Draw the ISO symbol of 3/2 DCV.

16. Mention any two applications of pneumatic

system.

17. What is lubricity of a fluid?

18. What is accumulator?

19. When the pressure intensifiers to be used

in hydrciuLics system?

20. Mention any two applications of hydraulic

system.

PART — B

21. (A) (i) Define (a) Specific gravity (b)

cohesion.

(ii) Explain hydraulic lift with neat sketch.

(Or)

(B) (i) An U-tube differential manometer

connects two pipes A and

B. The pipe A contains on oiL of specific

gravity 1.59 under a pressure of l00 kN/m2, The pipe B contains

water under a pressure of 80 kN/m2, The pipe A lies 2 m above the

pipe B. The centre of the pipe B is 0.5 m above the mercury level in the limb

which connects pipe A. Find the difference in levels of the mercury.

(ii) Explain the operation of diaphragm type

pressure gauge with sketch.

22. (A) (i) What are the assumptions made in

Bernoulli’s theorem?

(ii) Water

is supplied to a factory from a hydro power station by means of a pipe Line of

200mm diameter and 12 km long. The pressure at the power station is 45000 kN/m2.

Find the maximum power that can be transmitted to the factory. Assume F=0.028.

(Or)

(B) (i) The difference of heads between the

two ends of a pipe 400 m long and 480 mm diameter is 1.5 m. Taking Darcy’s coefficient

as 0.04, calculate the discharge through the pipe. Neglect minor losses.

(ii) Explain any two minor losses occurred in

fluid flow.

23. (A) (i) A jet of water 80mm diameter

moves with a velocity of 15 m/s and strikes a series of vanes moving with ci

velocity of l0 m/sec. Find (a) The force exerted by the jet (b) Work done by

the jet and (c) Co-efficient of jet.

(ii) Explain the working of a jet pump with

neat sketch.

(Or)

(B) (I) Explain the working of multi-stage

centrifugal pumps with neat sketches.

(ii) The piston of a single acting pump has a

diameter of 100 mm and a stroke of 200 mm. The pump raises the water to a height of 20 m at 50 rpm. Calculate the

theoretical discharge and power required if the efficiency is 90%.

24. (A) (i) Explain the working of 5/3 DCV

with neat sketch.

(ii) Explain the uses of shuttle valve in pneumatic

system with neat sketch.

(Or)

(B) (i) Explain the merits and demerits of

pneumatic systems.

(ii) Explain the automatic operation of

double acting cylinder with neat sketch.

25. (A) (I) Explain any one type of

accumulator with neat sketch.

(ii) Explain the working of vane pump with

neat sketch.

(Or)

(B) (i) Explain the hydraulic circuit for

milling machine tabLe movement with neat sketch.

(ii) Compare hydraulic and pneumatic systems.

Subscribe to:

Comments (Atom)