Thanks www.tndte.gov.in

****************

Open pdf drawings as pdf

***************

***********************************************************

Geneva wheel

****************

Open pdf drawings as pdf

***************

***********************************************************

Open Drawings redrawn by R.Ramakutty as pdf***********************************************************

AutoCAD

3D - Introduction

WCS and UCS

There are

two coordinate systems: a fixed system called the world coordinate system (WCS)

and a movable system called the user coordinate system (UCS). By default, these

two systems are coincident in a new drawing.

By default when we start a new (blank)

drawing we use the World Coordinate System (WCS). This is (0,0,0) point. The

square in the crosshairs of UCS indicates the World Coordinate System. Normally in

2D views, the WCS X axis is horizontal and the Y axis is vertical. The WCS

origin is where the X and Y axes intersect (0,0). All objects in a drawing file

are defined by their WCS coordinates. However, it is usually more convenient to

create and edit objects based on the movable UCS.

Moving or rotating the UCS can make it easier to work on

particular areas of a drawing.

We can relocate the user coordinate system by UCS command

- Move the UCS by defining a new origin point.

- Align the UCS with an existing object.

- Rotate the UCS by specifying a new origin point and a point on

the new X axis.

- Rotate the current UCS a specified angle around the Z axis.

- Revert to the previous UCS.

- Restore the UCS to be coincident with the WCS.

- View makes the ucsicon

parallel to drawing screen.

Regions are two-dimensional areas we

create from closed shapes or loops. Closed polylines, lines, and curves are

valid selections. Curves include circular arcs, circles, elliptical arcs,

ellipses, and splines.

Regions are two-dimensional enclosed areas that have

physical properties such as centroids

Creating 3D Solids

Presspull

Click inside bounded areas to press or pull

and drag the mouse in the required Z direction and enter the height

We can create a new solid or surface by

sweeping an open or closed planar curve (profile) along an open or closed 2D or

3D path.of bounded areas

Select the objects or

edge subobjects to extrude.

Specify the height and

taper angle or select the path

Closed polylines, circles

and regions are only extruded to 3d solids

SWEEP

Creates a 3D

solid or surface by sweeping a 2D object(region) along a path.

LOFT

Creates a 3D solid or surface in the space between

several cross sections. To create a solid by lofting, first create a

set of cross sections. Then click the Loft button on the Modeling Toolbar.

REVOLVE

Select a closed region or closed

polyline to revolve.

To set the axis of revolution,

specify one of the following: The start and endpoint. Click to points on the

screen to set the axis orientation. ...

Press

Enter. To create a 3D solid the angle must be 360 degrees.

SLICE

Specify two points to define the

cutting plane.

Specify which side of the sliced object

to retain, or enter b (Both) to retain both sides.

UNION

Combines

selected 3D solids, surfaces, or 2D regions by addition.

SUBTRACT

Select the objects that you want to keep,

press Enter, then select the objects that you want to subtract. Objects

in the second selection set are subtracted from objects in the

first selection set.

INTERSECT

VISUALSTYLES

Creates and modifies visual styles and applies a visual

style to a viewport.

Create a

rectangular or cubical solid box.

Create a

solid wedge with rectangular or cubical faces.

Create a

pointed or frustum of a cone with a circular or elliptical base.

Create a

solid cylinder with a circular or elliptical base.

Create a

solid sphere using one of several methods.

Create a

solid pyramid with up to 32 sides.

Create a

ring-shaped solid that resembles the inner tube of a tire.

Solview

This command automates the manual process of

creating views, layers, and layout viewports for 3D models.

Note SOLVIEW must

be run on a layout tab. If the Model tab is current, the last active layout tab

is made current.

SOLVIEW places the viewport objects on the VPORTS layer,

which it creates if it does not already exist. The view-specific information

that is saved with each viewport you create is used by SOLDRAW to generate

the final drawing view.

SOLVIEW creates layers that SOLDRAW uses to place the

visible lines and hidden lines for each view, view

name-VIS, view name-HID,

view name-HAT, and a layer where

you can place dimensions that are visible in individual viewports, view name-DIM.

Soldraw

After using SOLVIEW, visible and hidden lines

representing the silhouette and edges of solids in the viewport are created and

then projected to a plane perpendicular to the viewing direction.

Select viewports to draw ...

Select objects: Select the

viewports to be drawn

3DROTATE : In a 3D view, displays the 3D

Rotate gizmo to aid in revolving 3D objects around a base point.

3DARRAY : For 3D rectangular

arrays, in addition to columns and rows, you also specify the number of levels

in the Z direction.

Enter the number of items in the

array

Specify the angle to fill (+=ccw,

-=cw) <360>

The specified angle determines how far the objects are

arrayed about the axis of rotation. A positive number produces a

counterclockwise array rotation. A negative number produces a clockwise array

rotation.

Rotate arrayed objects? [Yes/No]

<Y>: Enter y or n, or press Enter

3D Mirror.

Select the object to mirror.

Specify three points to define a mirroring plane.

Press Enter to retain the original objects, or enter y to delete

them.

Align.

Select the objects that

you want to align.

Specify a source point and

then the corresponding destination point. To rotate the object, specify a

second source point followed by a second destination point.

Press

Enter to end the command

Aim

:

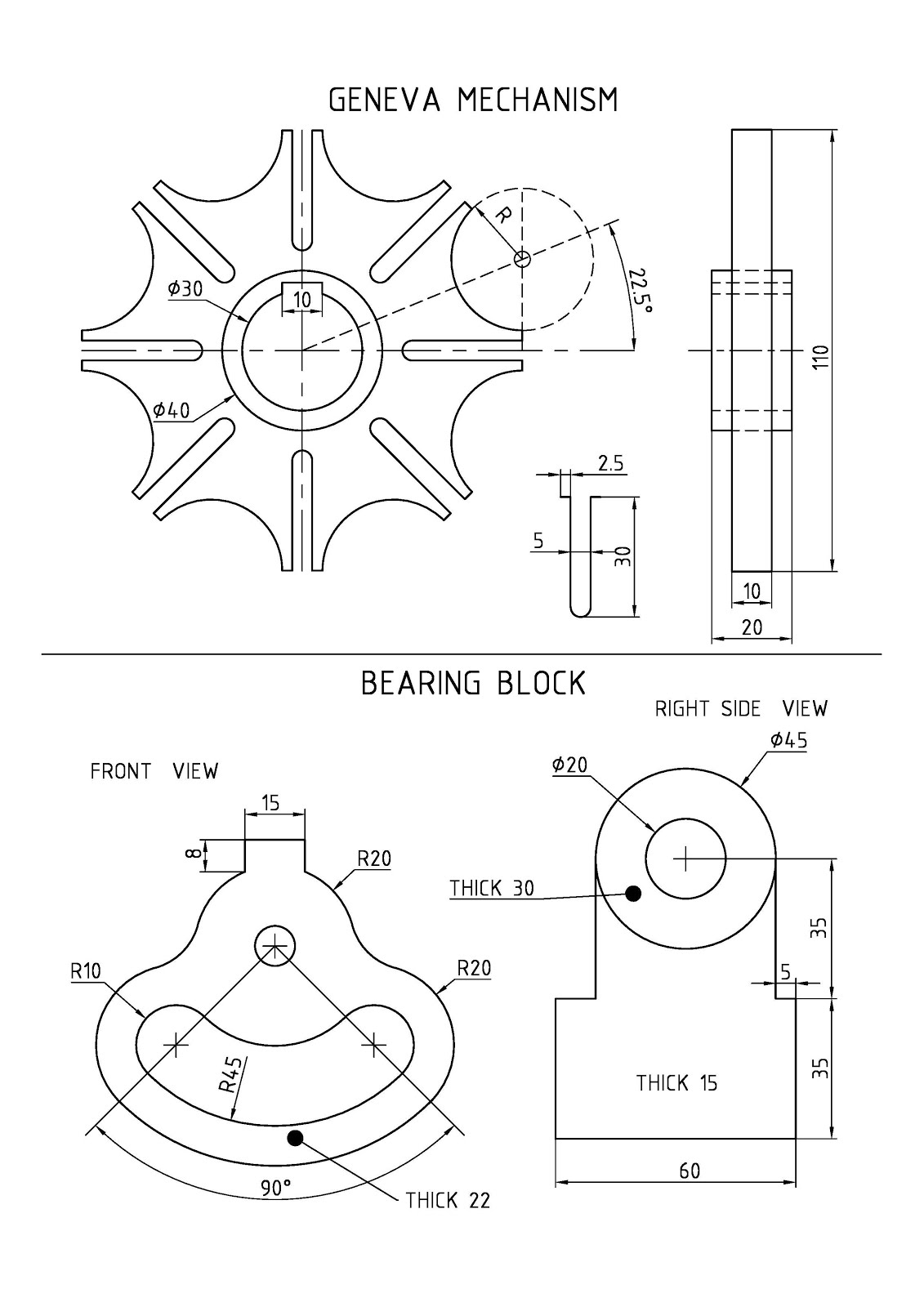

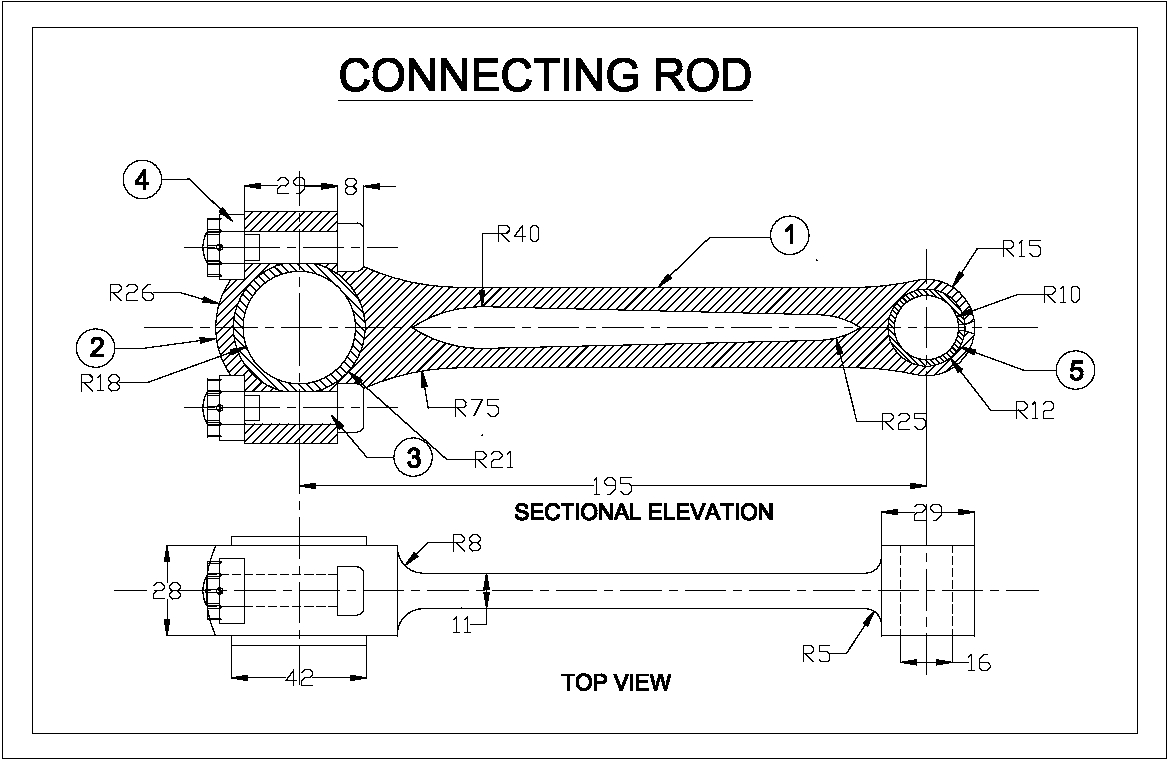

To draw the geneva wheel 3d drawing

in AutoCad

Procedure

:

|

1. Hub:

|

Draw 2 concentric circles of radius 15 mm and 20

- Circle with center

point, radius option.

|

Draw the keyway (10 mm X 3 mm) -

Line, Offset, Trim

|

2. Wheel

|

Draw the top half of slot at 25 mm from the center of the hub(2.5 mm 30 mm x 2.5 mm ). - Line, Offset, Trim

|

Fillet the inner end with radius 2.5.

|

Mirror the bottom half.

|

Make a polar array of 8 slots.

|

Draw the circular arc between two

successive slots. (Line at 22.5

degree, line of 55 mm =radius of geneva wheel & vertical line from last

line, Circle, Trim)

|

Make a polar array of 8

arcs.

|

3. 3D Solid

Modeling

View

toolbar à SE Isometric view

|

Modeling

Toolbar à Presspull

Presspull

the the hub by clicking inside between

two circles to half thickness ( 10 mm ) in Z direction

|

Presspull

the the wheel by clicking inside between

hub and outline to half

thickness ( 5 mm ) in Z direction

|

View toolbar

à Front view

Mirror the bottom

half

|

Modeling

Toolbar à Union

Union the

two halves.

View

toolbar à SE Isometric view

|

Visual

Styles Toolbar à Conceptual , 2D

wireframe, 3D Hidden etc

|

4. Isometric view & Orthographic views

SOLVIEW must be run on a layout tab. If the Model

tab is current, the last active layout tab is made current

To create

isometric view , Set

UCS à View and give Solview à Ucsà

Current Ucs

Change view to main view (Front or Top view) in Model Tab

|

RESULT

:

The geneva wheel 3d drawing is drawn in AutoCAD

Bearing block

Aim :

To

draw the bearing block 3d drawing in AutoCAD

Procedure :

Bottom

portion of block

1.View

toolbar à

Front View

2.

Draw two lines from a point A à at -45 degree and at -135

degree.

3.

Draw three concentric circles of radius

45, 55, and 25 mm , with intersection point A as centre.

4.

Trim the circles outside the two lines

5.

Draw circles with 2P – 2 Point

option to connect circles of radii 25, 45 mm.

6.

Draw three circles of 20 mm radius with the centres of last drawn circles(R10)

and “A” point as centres. Draw a circle

of 5 mm radius with “A” point as centre

7.

Fillet the 20 mm radius circles on the left side and right side – with Radius = 15 mm.

8.

Draw the rectangle of 15 mm x 8 mm, at the top symmetrically.( Line, Offset and

Trim commands)

9.

Trim the unnecessary edges.

10.

View toolbar à

SE isometric View . Presspull -

click between outer and inner edges and pull

to Z-Thickness of 22 mm.

Middle and

top portion of block.

11.

View toolbar à

Right side View

12.

Draw a series of lines :: 60 mm to the right , 35 mm to the top, 5 mm to the

left, 35 mm to the top, 45 mm to the left, 35 mm downwards, 10 mm to the left

and 35 mm downwards.

13.

With midpoint of 45 mm line as centre, draw concentric circles of 22.5 mm and

10 mm radii.

14.

Erase 45 mm line.

15.

View toolbar à

SE isometric View. Presspull -

click inside the middle portion and pull

to Z-Thickness of 15 mm. Presspull -

click between outer and inner

circles and pull to Z-Thickness of 35 mm

16.

Move the the top portion 5 mm the right.

17.

Union the Middle and top portions.

Assembly

18.

Assemble and union the portions – Move and Union

19.

Isometric view & Orthographic views

creation :SOLVIEW must be run on a layout tab. If the Model tab

is current, the last active layout tab is made current.To create isometric

view , Set UCS à View and give Solview à Ucsà Current Ucs.Change view to main view (Front or Top view) in Model Tab

RESULT

:

The bearing block 3d drawing is drawn in AutoCAD

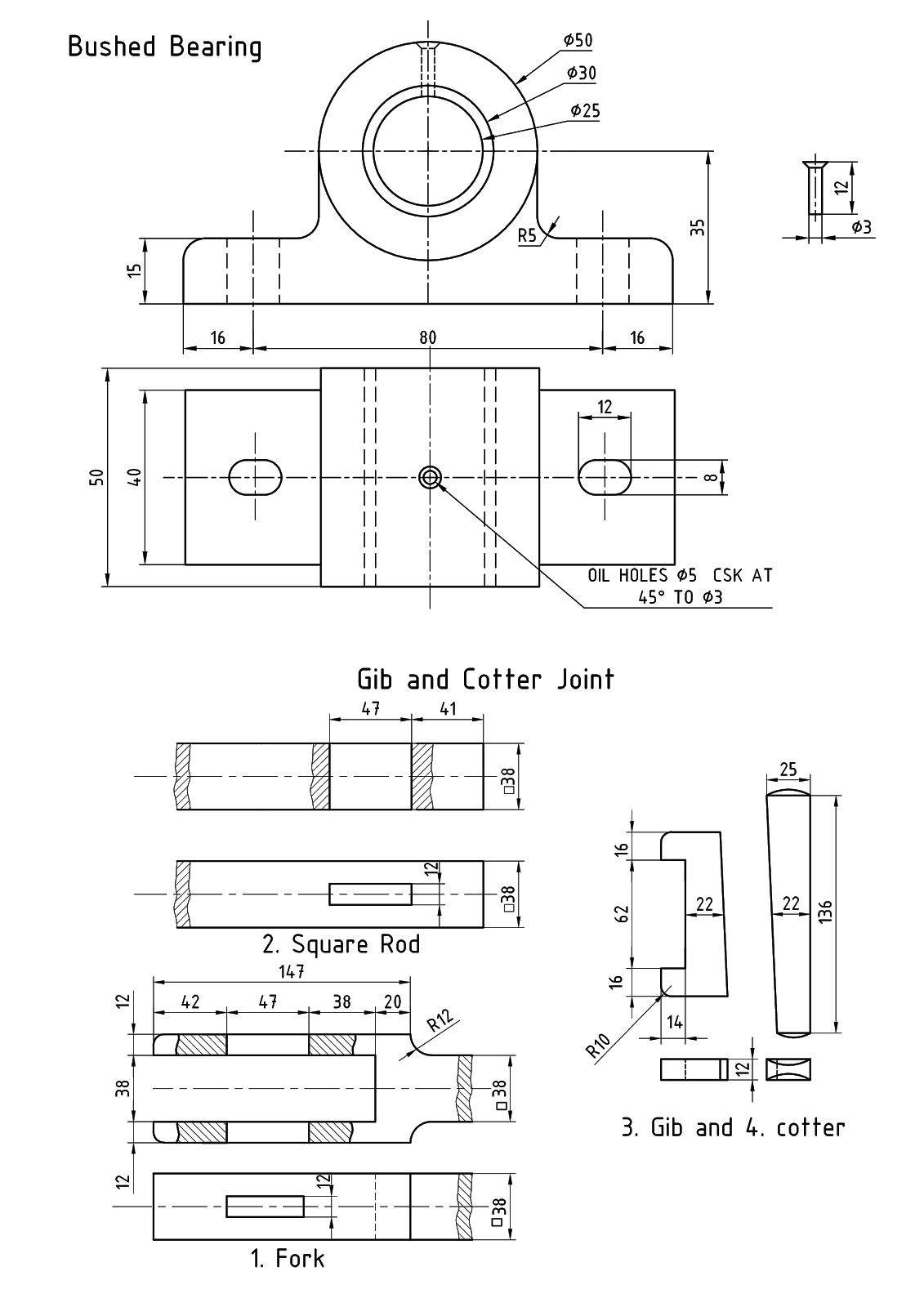

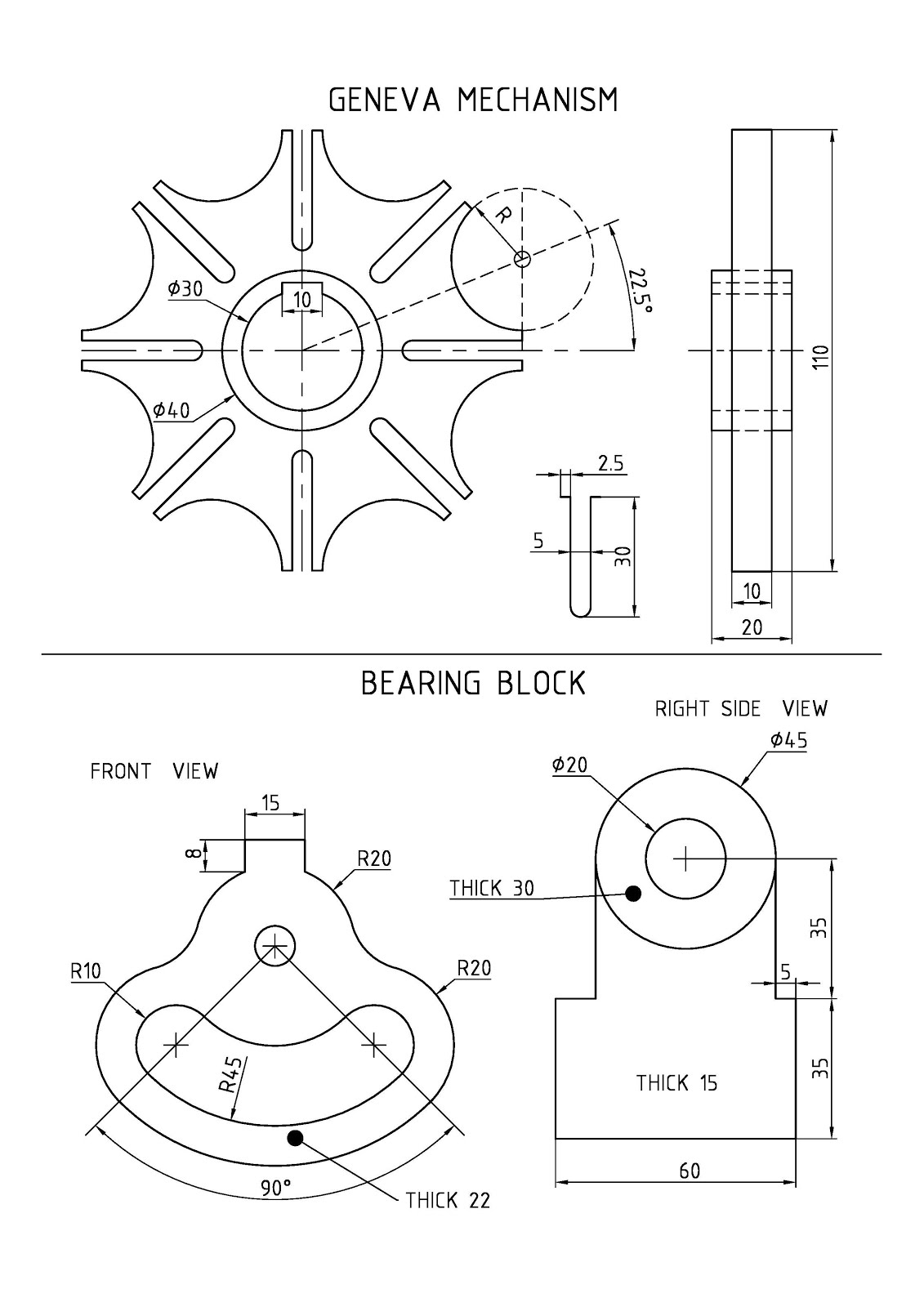

Bushed bearing

Aim

To draw the bushed bearing 3d

drawing in AutoCAD

Procedure

:

Half Block

(or) Half Body

1.View

toolbar à

Front View

2.

Draw a rectangle of 112 x 15 (Command : Rectang

, Explode(X) or Line)

3.

Draw two concentric circles of radius 25 and 16 mm at a height of 35 from the

base of rectangle.

4.

Draw vertical lines from the horizontal quadrant

points of the 25 mm radius circle downwards.

5.

Fillet with Radius 5 mm on both sides

6.

View toolbar à

SE isometric View . Presspull -

click between outer circle and bottom rectangle and pull to Z-Thickness of 20 mm.(half

thickness)------bottom of body

7. Presspull

- click between circles and pull

to Z-Thickness of 25 mm.(half thickness)

---------

top of body.

Bush (Draw full bush)

8.

View toolbar à

Front View

9.

Draw two concentric circles of radius 12.5

and 16 mm

10.

View toolbar à

SE isometric View . Presspull -

click between circles and pull

to Z-Thickness of 50 mm.(half thickness).

Full Block

11.

View toolbar à

Right Side View or Top View

12.

Mirror the other half of block .

13.

Union the the halves of block .

Slot & fillet at Rectangular

Base

14.

View toolbar à

Front View . Draw the slots at top of

rectangular base at both ends

15.

View toolbar à

SE isometric View . Presspull -

click in the slot area and press downwards

to make slot.

16.

Fillet the rectangular base at both ends.

Oil hole

17.

Make oil holes for block (Cone, Cylinder and union or two circles and loft) and bush (Cylinder) with extra length at the

bottom side at the top UCS in the SE Isometric view.

18.

Move the oil holes to block and bush repectively and Subtract.

Assembly

19.

Move bush to block.

RESULT

:

The bushed bearing 3d drawing is drawn in AutoCAD

8. View toolbar à Top View

8. View toolbar à Top View

4. Gib and Cotter Joint

Aim :

To

draw the Gib and Cotter Joint 3d drawing in AutoCAD

Procedure :

1.

View toolbar à

Front View

2.

Draw the fork rod, square rod, gib and cotter.(Commands: Line, Rectang, Fillet,

Offset, Trim, Mirror)

3.

View toolbar à

SE isometric View .

4. Presspull - click inside the fork area and pull to

Z-Thickness of 38 mm

5.

Presspull - click inside the square rod area and pull to

Z-Thickness of 38 mm.

6.

Presspull - click inside the gib area and pull to

Z-Thickness of 12 mm.

7.

Presspull - click inside the cotter area and pull to

Z-Thickness of 12 mm.

9.

View toolbar à

SE isometric View (Or) UCS II toolbar à

Top UCS (Or) World UCS

10.

Draw a rectangle for slot in the

fork rod and square rod. Copy the rectangle to top face of the fork rod and

square rod. Presspull - click inside the rectangle and press downwards outside

the solid ---- in the fork rod. (Separately for the square rod)

Assembly

11.

Move the square rod to the fork rod.

Move gib and cotter

RESULT

:

The Gib and Cotter Joint 3d drawing is

drawn in AutoCAD

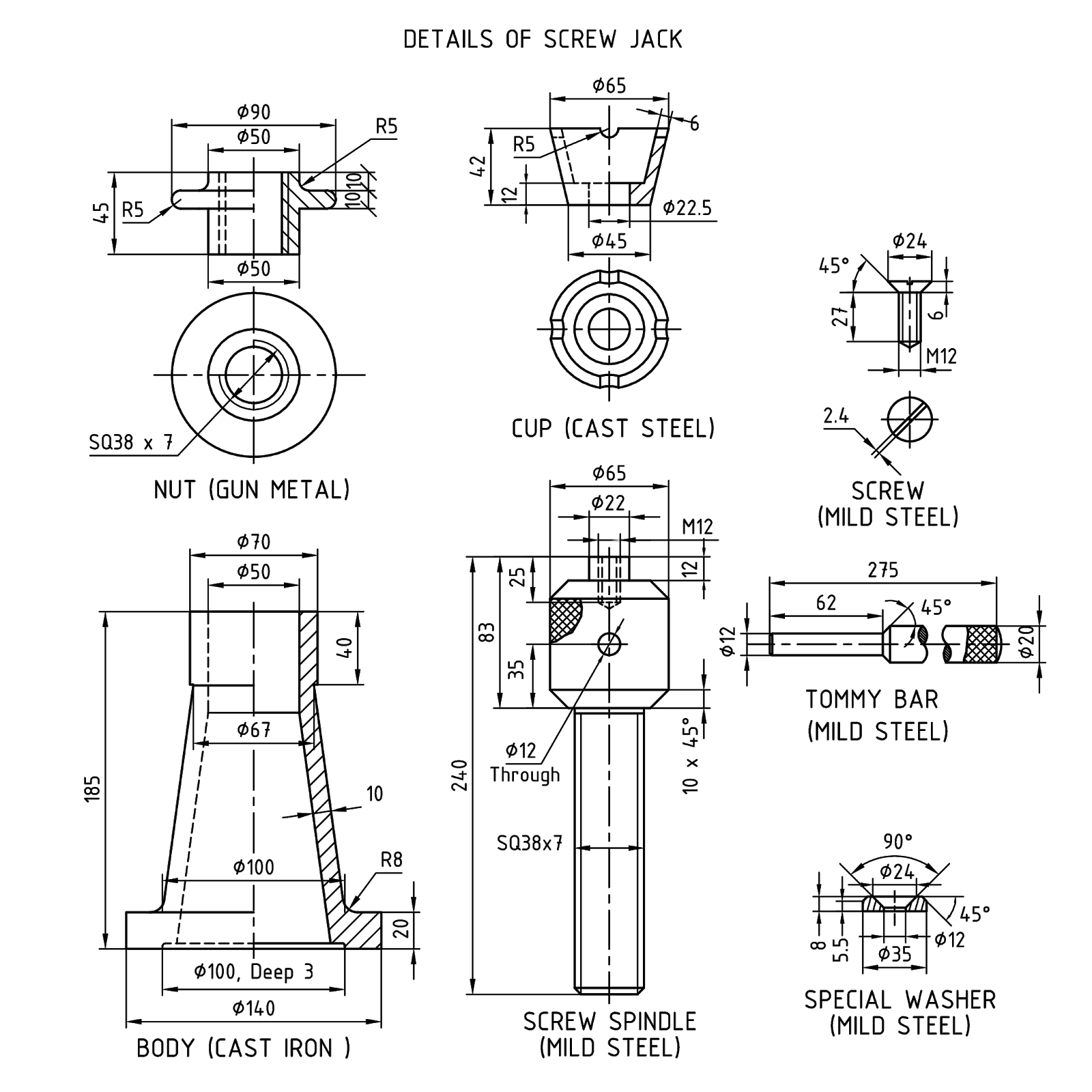

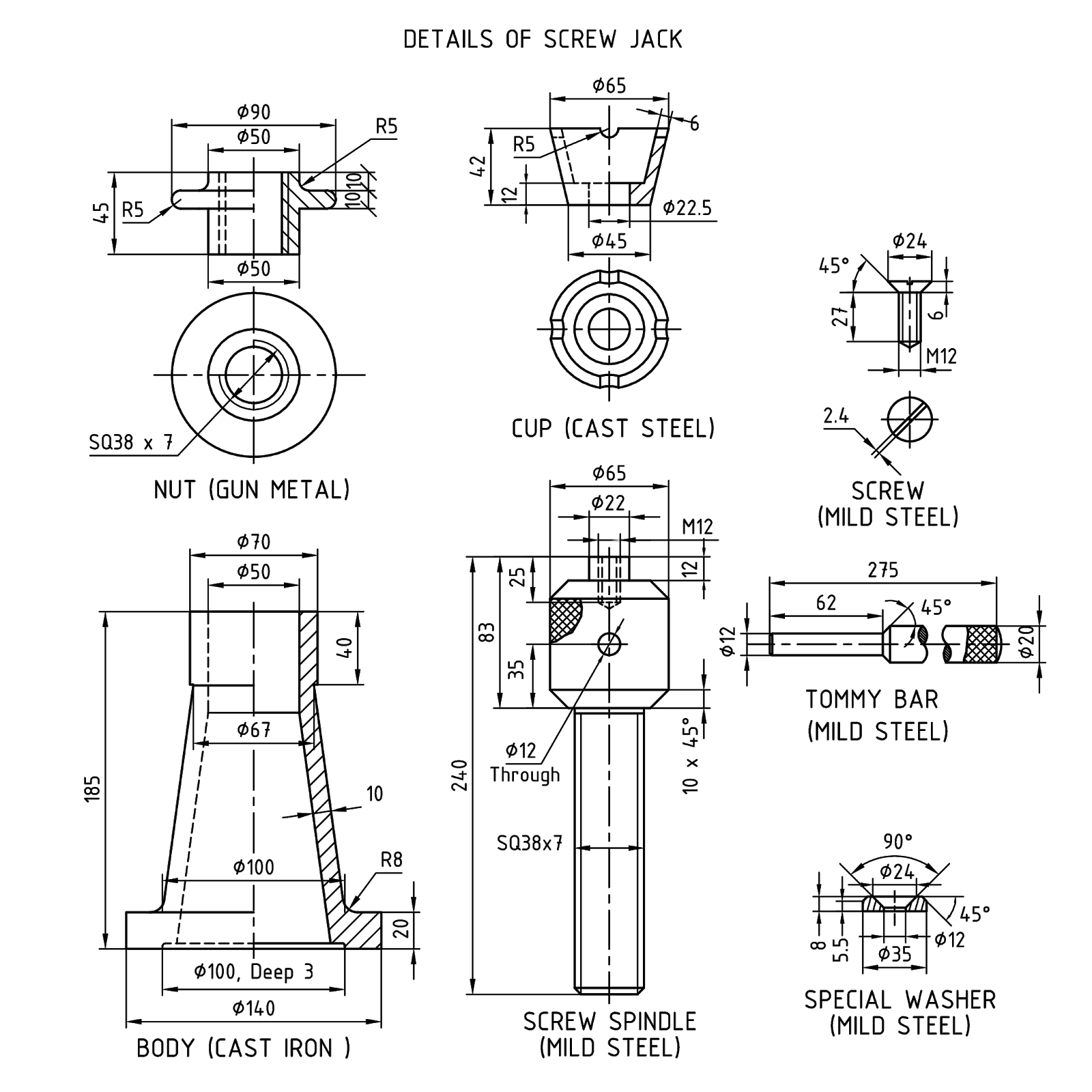

5. Screw Jack

Aim :

To draw the Screw Jack 3d drawing in AutoCAD

Procedure :

1. View

toolbar à

Front View

2. Create body of the Screw Jack :

Construct the half of the cross section and an

axis line for revolution.

Use Region

(Reg) command to create the closed 2d area.

Use Revolve

(Rev) command to create the 3d solid.

Select

the region and press enter

Specify

the start point of axis

Specify

the end point of axis

Specify

angle of revolution <360> : press enter

3. Similarly create all other parts

v Nut

v Screw Spindle

v Cup

v Special washer

v Set Screw

v Tommy Bar

4. Create a

hole in the screw spindle (A) at top

Copy the shank of the

set screw (b)at the top of the screw spindle

Subtract: select A first, press

enter and select B next and press enter. (A-B)

5. Create a

hole in the screw spindle at side.

Make a cylinder. Move

the cylinder to the screw spindle

Subtract this cylinder

from the screw spindle

6. Similarly

draw the half circular slots in the cup and slot in the set screw.

7. Assembly :

Move

the nut to the body.(align bottom of center of the collar of the nut à top center of body).

Move

the screw spindle to the nut.(align top center of the nut à bottom center of screw spindle head) and again move

the screw spindle upwards by 10 mm.

Move the cup to the screw spindle

(align bottom center of the cup à top center of screw

spindle head)

Move the washer and set screw.

RESULT :

The Screw Jack 3d drawing is drawn in AutoCAD.

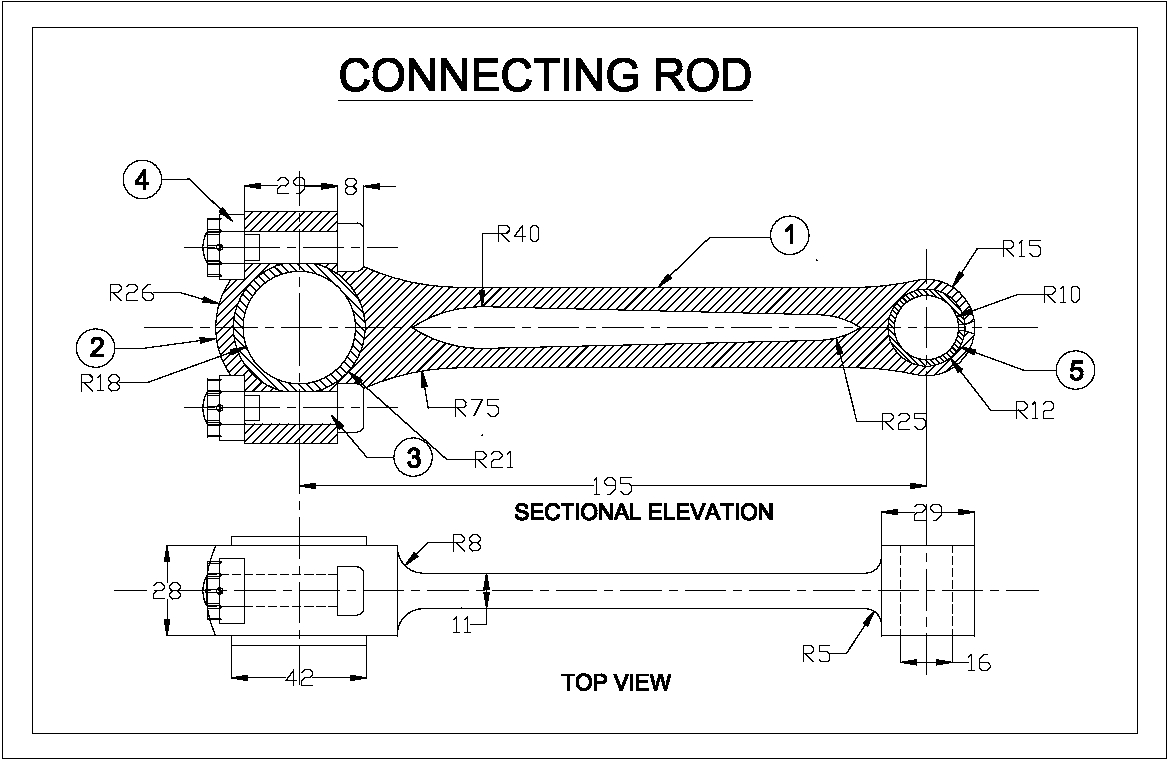

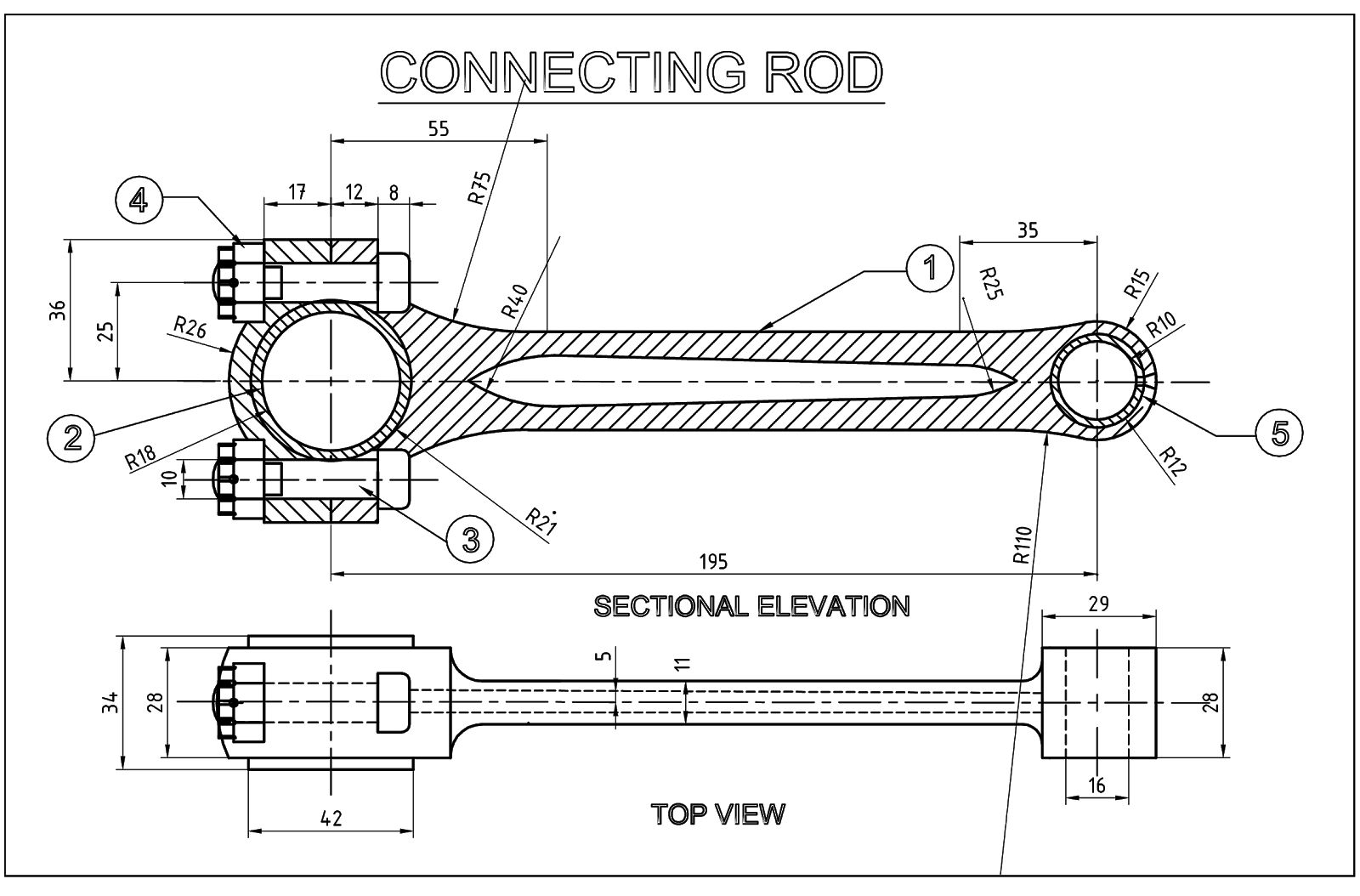

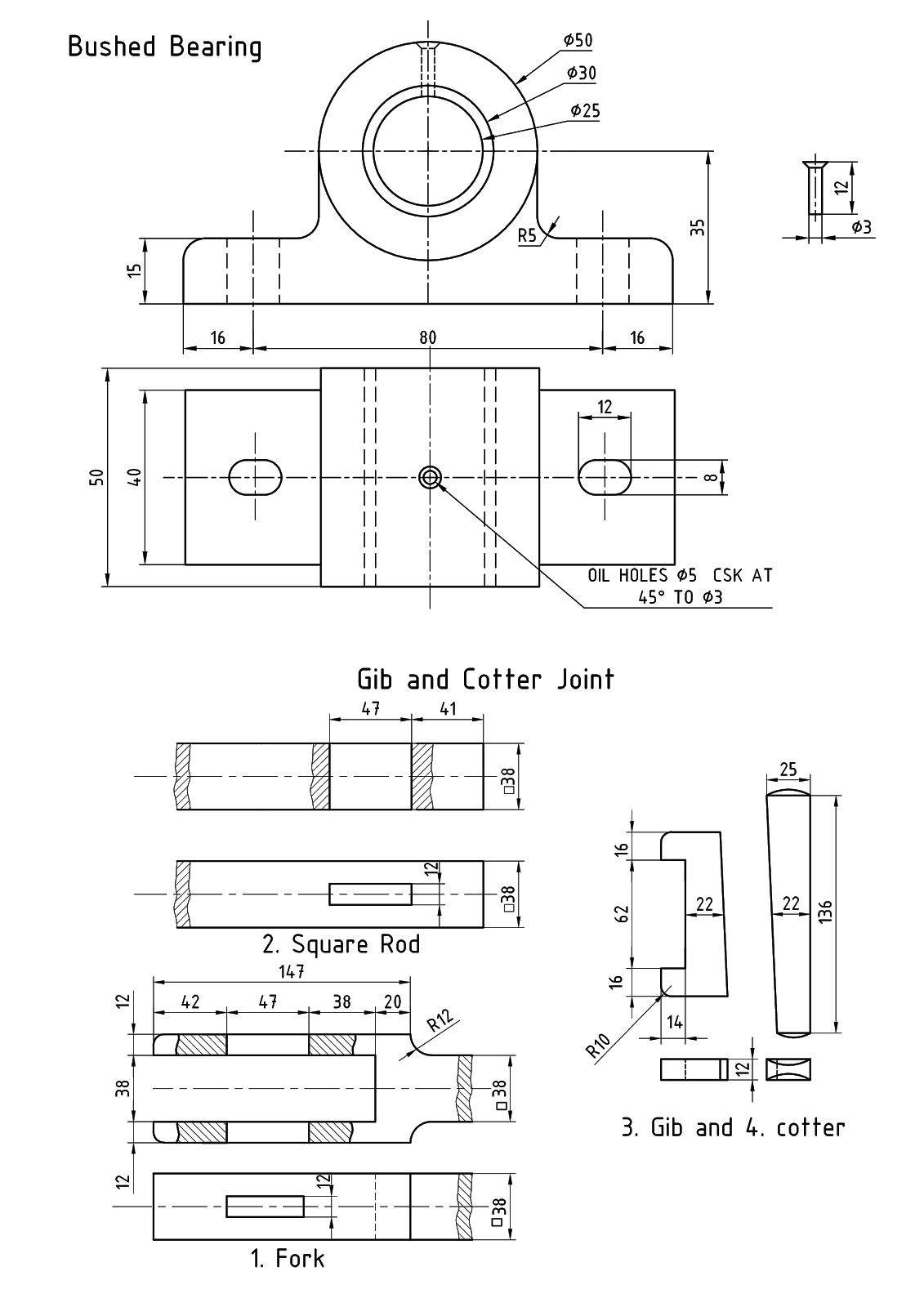

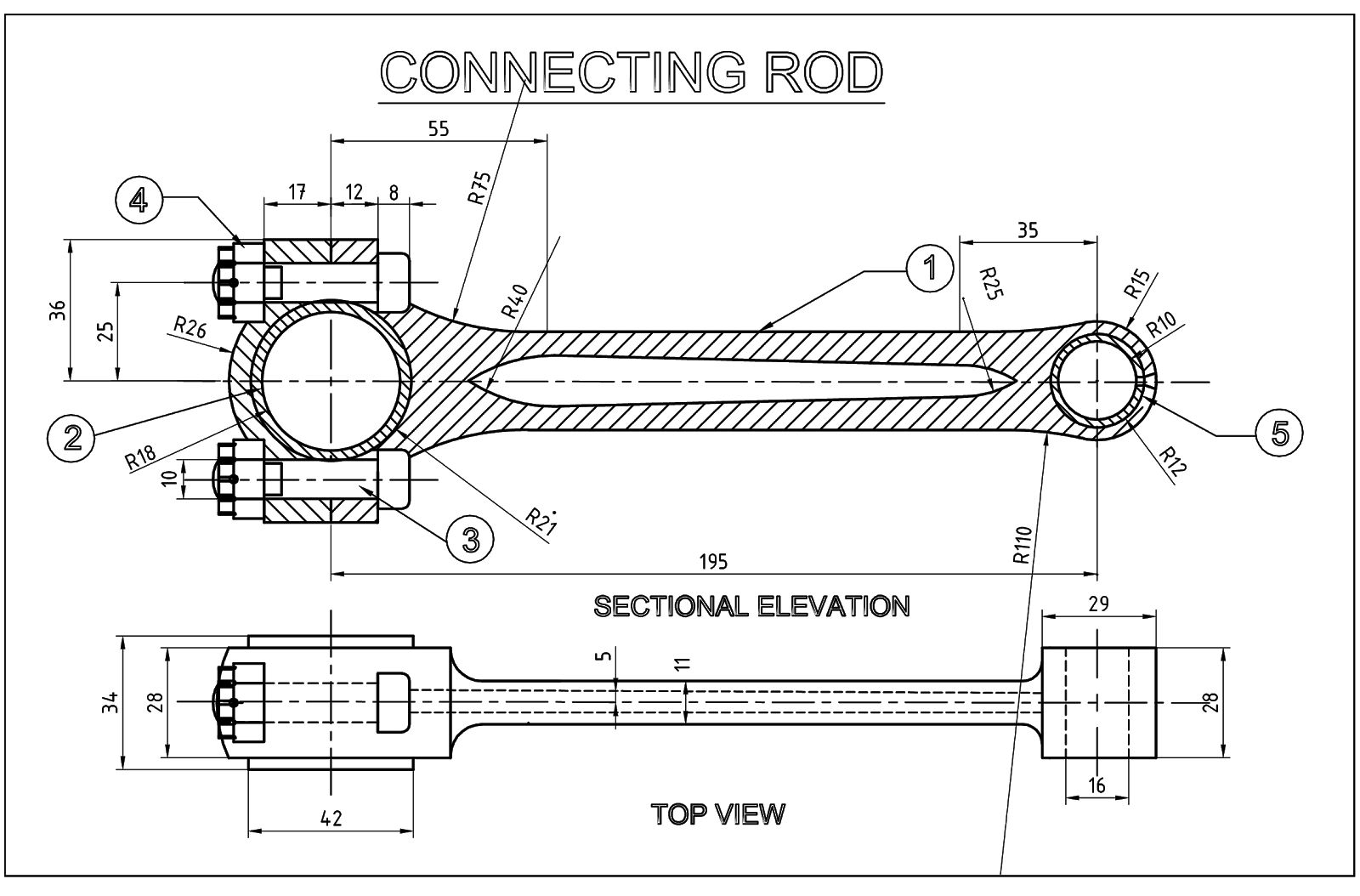

6. Connecting Rod

Aim :

To draw the Connecting Rod 3d drawing in

AutoCAD

Procedure :

1. View

toolbar à

Front View

2. Draw the big end and bush

Draw the small end and bush

Draw the I section connecting big end and small end

3. View toolbar à SE

Isometric View

4. Presspull

all the parts to half thickness.

Presspull big end

Presspull big end bush

Presspull small end

Presspull small end bush

Presspull the I-section flange

Presspull the I-section web or rib

5. View

toolbar à

Right Side View or Top view

Mirror all the parts

Union

6. View

toolbar à

SE Isometric View

UCS II toolbar à Right UCS

Make holes in top and bottom of the

big end

7 Split the

big end by Slice (SL) command.

8. Make

bolts and join the ends.

RESULT :

The Connecting Rod 3d drawing is drawn in AutoCAD.