Thursday, 28 December 2017

Monday, 18 December 2017

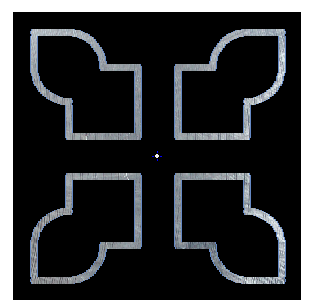

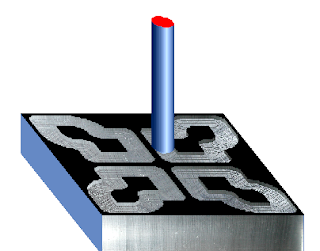

Mirror CNC Program in M Scheme using CNCTRAIN SOFTWARE

M06 T01

M03 S2000

G00 Z5.

G00 X0. Y0.

M98 P1111

M70

M98 P1111

M80

M71

M98 P1111

M81

M70

M71

M98 P1111

M80

M81

M05

M30

O1111

|

| TOOL DIA 1 MM |

G01 Z-5. F80.

G91

G01 X24. F80.

G01 Y12. F80.

G03 X12 .Y12. R12.

G01 Y12.

G01 X-12.

G03 X-12.Y-12. R12.

G01 X-12.

G01 Y-24.

G90

G00 Z5.

|

| TOOL DIA 10 MM |

M99

*************************************

Program written by R.Ramakutty

Sunday, 17 December 2017

geneva :: http://benbrandt22.github.io/genevaGen/

https://en.wikipedia.org/wiki/File:Geneva_mechanism_6spoke_animation.gif

http://benbrandt22.github.io/genevaGen/

3. Geneva mechanism

Fig. 4.5.3 Geneva mechanism

The Geneva drive is also commonly called a Maltese cross mechanism. The Geneva mechanism translates a continuous rotation into an intermittent rotary motion. The rotating drive wheel has a pin that reaches into a slot of the driven wheel. The drive wheel also has a raised circular blocking disc that locks the driven wheel in position between steps (Fig. 4.5.3). There are three basic types of Geneva motion mechanisms namely external, internal and spherical. The spherical Geneva mechanism is very rarely used. In the simplest form, the driven wheel has four slots and hence for each rotation of the drive wheel it advances by one step of 90°. If the driven wheel has n slots, it advances by 360°/n per full rotation of the drive wheel.

In an internal Geneva drive the axis of the drive wheel of the internal drive is supported on only one side (Fig. 4.5.4). The angle by which the drive wheel has to rotate to effect one step rotation of the driven wheel is always smaller than 180° in an external Geneva drive and is always greater than 180° in an internal one. The external form is the more common, as it can be built smaller and can withstand higher mechanical stresses.

Fig. 4.5.4 Internal Geneva mechanism

Because the driven wheel always under full control of the driver, impact is a problem. It can be reduced by designing the pin in such a way that the pin picks up the driven member as slowly as possible. Both the Geneva mechanisms can be used for light and heavy duty applications. Generally, they are used in assembly machines.

Intermittent linear motion from rotary motion can also be obtained using Geneva mechanism (Fig. 4.5.5). This type of movement is basically required in packaging, assembly operations, stamping, embossing operations in manufacturing automation.

Subscribe to:

Comments (Atom)